- Buy

- Rent

- Parts & Services

- Technology

- My Account

- Learn

- Careers

- Contact

Specifications

Units:

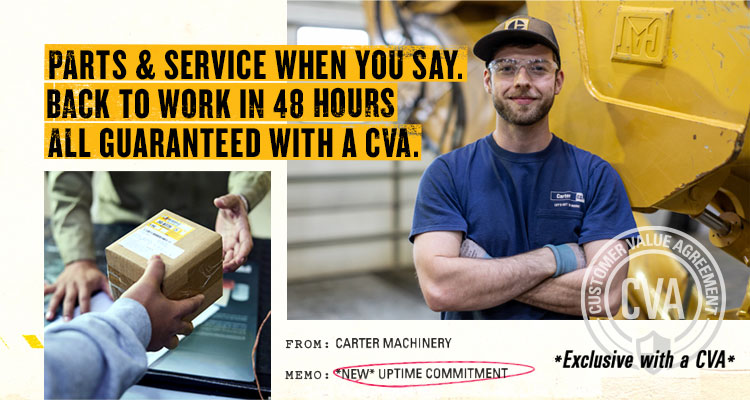

CUSTOMER VALUE AGREEMENT (CVA) UPTIME COMMITMENT: BACK TO WORK IN 48 HOURS

With the new Uptime Commitment—included with every CVA—you get next-day maintenance, wear, and repair parts* and immediate service response**, guaranteeing you’re back to work within 48 hours.***

Learn More

Rent a Boom Lift Get a Cat Cooler Free

For a limited time, rent any eligible boom lift for a month and score a rugged, 27-quart yellow Cat® Cooler free!

Learn More

SPECIAL FINANCING ON CAT® REBUILDS

Rebuild now and repay later while giving your machine (and your budget) a longer life. For a limited time, get 0% financing for 36 months on any Cat® rebuild performed in a Carter shop when you use your Cat Card account. Cat equipment and components are built to deliver performance over multiple lifetimes – don’t let that built-in value go to waste. Take advantage of this special offer today.

Learn More

SPECIAL FINANCING ON CAT® UNDERCARRIAGE

Upgrade your undercarriage without the upfront costs! Now through December 31, take advantage of limited-time 0% financing for 36 months on Cat® undercarriage parts when you use your Cat Card. Plus, the option to skip your first six payments. Don't wait, apply today or contact your product support rep to get started!

Learn More

Don't Let a Downed Machine Slow You Down

This summer, take advantage of our exclusive rental offer: While your machine is being rebuilt at a Carter shop, you'll get a three-month rental for the price of one month!

Learn More

CUSTOMER VALUE AGREEMENT (CVA) SERVICE RESPONSE GUARANTEE

When you have a Carter Customer Value Agreement (CVA) with Labor, you get service on your terms – because your time matters. Need service today? We’ll be there. Prefer to schedule it later? We’ll be there when you say.

Learn More

Cat® Central App

Cat® Central is the must-have mobile app that provides instant access to telematics data, expert support, and genuine Cat® parts helping you effortlessly maximize your equipment uptime.

Learn More

LIMITED-TIME 0% FOR 36 MONTHS FINANCING + CAT® CVA

Smart power modes. Efficient engines. Advanced hydraulics. Cat® excavators come packed with features that raise your money-making potential. With limited-time financing, now is the time to save big on these mighty machines.

Learn More

25% OFF CAT® GROUND ENGAGING TOOLS (GET)

Is it about time to swap out your old bucket teeth and cutting edges? All Cat GET parts are now 25% off when you order in-store or online! No promo code needed!

Learn More

Get 25% Off Cat Rubber Tracks

For a limited time, take advantage of 25% off Cat® rubber track when you purchase online through the Cat Central app or parts.cat.com. Use promo code TRACK25 at checkout to apply the discount!

Shop Now

0% Financing for 12 Months on Select New Cat Work Tools

Cat® Work Tool attachments increase your machine’s productivity and expand its utility to accommodate your specific jobsite needs.

Save now

30-Minute Hydraulic Hose Repair - Guaranteed!

When hose failure happens, Carter Machinery's hydraulic hose repair experts are dedicated to getting you back to work faster. And now, at select locations, we’ll build you a replacement in less than 30 minutes or it's free!*

Learn More

CAT® ADVANSYS™ GROUND ENGAGING TOOLS

Convert to Cat® Advansys™ today and receive Free Adaptors for your wheel loader or excavator. Plus, for select equipment you could get 50% off Base Edge + Base Edge Assemblies*. Take advantage of this special offer today.

Learn More

Cat® Certified Rebuild Program

The Cat® Certified Rebuild Program will transform your end-of-life machines, systems, and components into like-new condition – at a fraction of the cost of buying new. Take advantage of 23% off parts for your in-shop repair, plus get a 3-year, 5,000-hour Extended Protection Plan (EPP). Financing options available, too!

Save Now

Fuel Payback Credit + CVA

Our Fuel Payback Credit delivers an immediate return on your new machine investment. Buy a qualifying new Cat Dozer, Excavator, Motor Grader, Track Loader, or Wheel Loader and get account credit for the first 1,500 hours or 24 months of fuel (whichever comes first).

Learn More

What’s Important To You? Manage Your Communication Preferences With Us