Home > Blog

Blog

MAKE FLUID & FILTER CHECKS PART OF YOUR DAILY PREVENTIVE MAINTENANCE PLAN

Protecting your investment and reducing unplanned downtime starts with conducting daily inspections of your equipment’s filters and fluids. Read on for some of our best practices that will help maximize your productivity.

Read More

How to Choose the Right Undercarriage for Your Cat® Machine

Did you know that undercarriage typically represents up to 50% of your machine’s owning and operating expenses? That’s why choosing the right system can significantly impact your machine’s performance, uptime, and long-term cost of ownership.

Read More

Protect Workers From Deadly Trench Collapses

June is Trench Safety Month and a critically important opportunity to increase awareness about the dangers and deaths that occur annually as a result of trench and excavation collapses. According to the CDC, 14 workers died on the job in 2023 due to trench collapses.

Read More

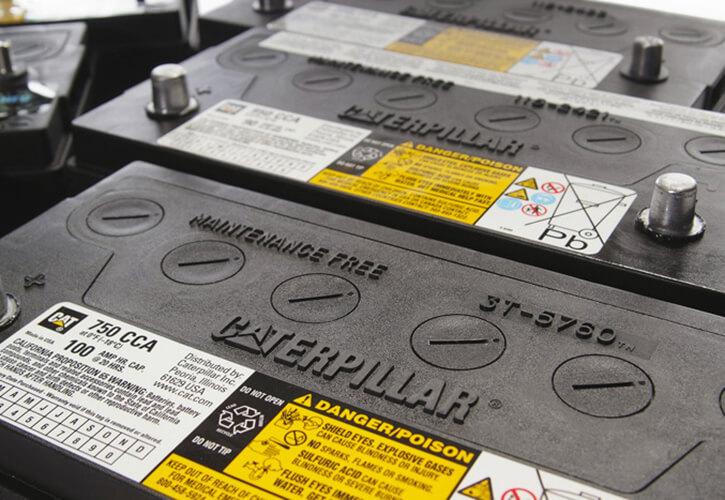

Best Practices for Battery Safety and Storage

Powering your equipment and your productivity starts with a reliable battery. That’s why Cat® batteries are designed to deliver unmatched performance, durability, and starting ability in temperature extremes when compared to other batteries…

Read More

Best Practices for Battery Selection and Installation

Powering your equipment and your productivity starts with a reliable battery. That’s why Cat® batteries are designed to deliver unmatched performance, durability, and starting ability in temperature extremes when compared to other batteries…

Read More

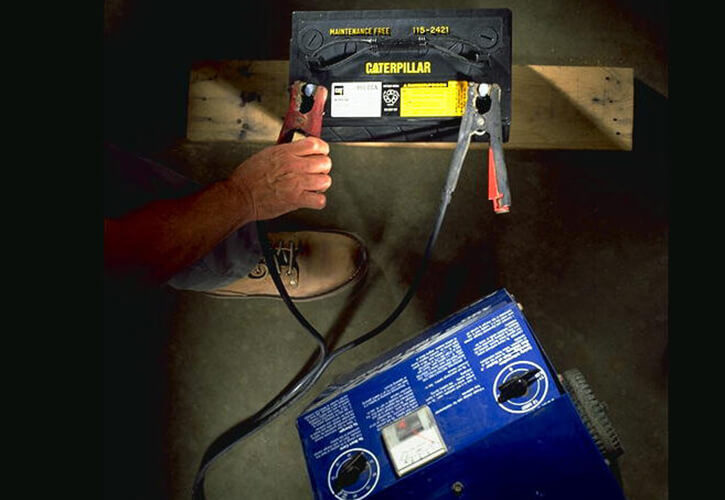

Best Practices for a Safe, Successful Battery Jump Start

Sometimes even the best battery needs a jump start. Maybe it was because an accessory was inadvertently left on or the equipment hadn’t been started in a while. While a dead battery is undoubtedly an annoyance and a delay, the good news is it’s usually a quick fix. All that’s needed is another fully charged…

Read More

Prevent Irrigation System Damage This Winter

The irrigation system that provides your lawn, nursery, or crops with life-sustaining water throughout the growing season is susceptible to significant winter damage if all the water isn’t removed from the complex network of under- and above-ground pipes and hoses before temperatures fall below freezing. And, contrary to popular belief, simply “winterizing” the system by…

Read More

VisionLink Video Series

We’re rolling out a five-part series of videos to help you gain a better understanding of the new Cat® VisionLink® product and how its robust data will enable you to make better decisions and remove guesswork from fleet management.

Read More

Be Wary Of Winter’s Hold On Your Machinery

Get a jump on winterizing your equipment so you don’t get left out in the cold. Take the proper precautions and your equipment will persist through the most frigid conditions. Get Things Started If your fleet sits in the cold all night your machinery will need time to get warmed up. Fluids need to circulate,…

Read More

How to Maintain Cat® Steel Tracks

Your equipment’s steel track is essential to its productivity. That’s why in this two-minute video, we’re sharing best practices for taking care of the track and its components. You’ll see why a daily track check is important, how cleaning debris from the track can help you spot problems and prevent…

Read More