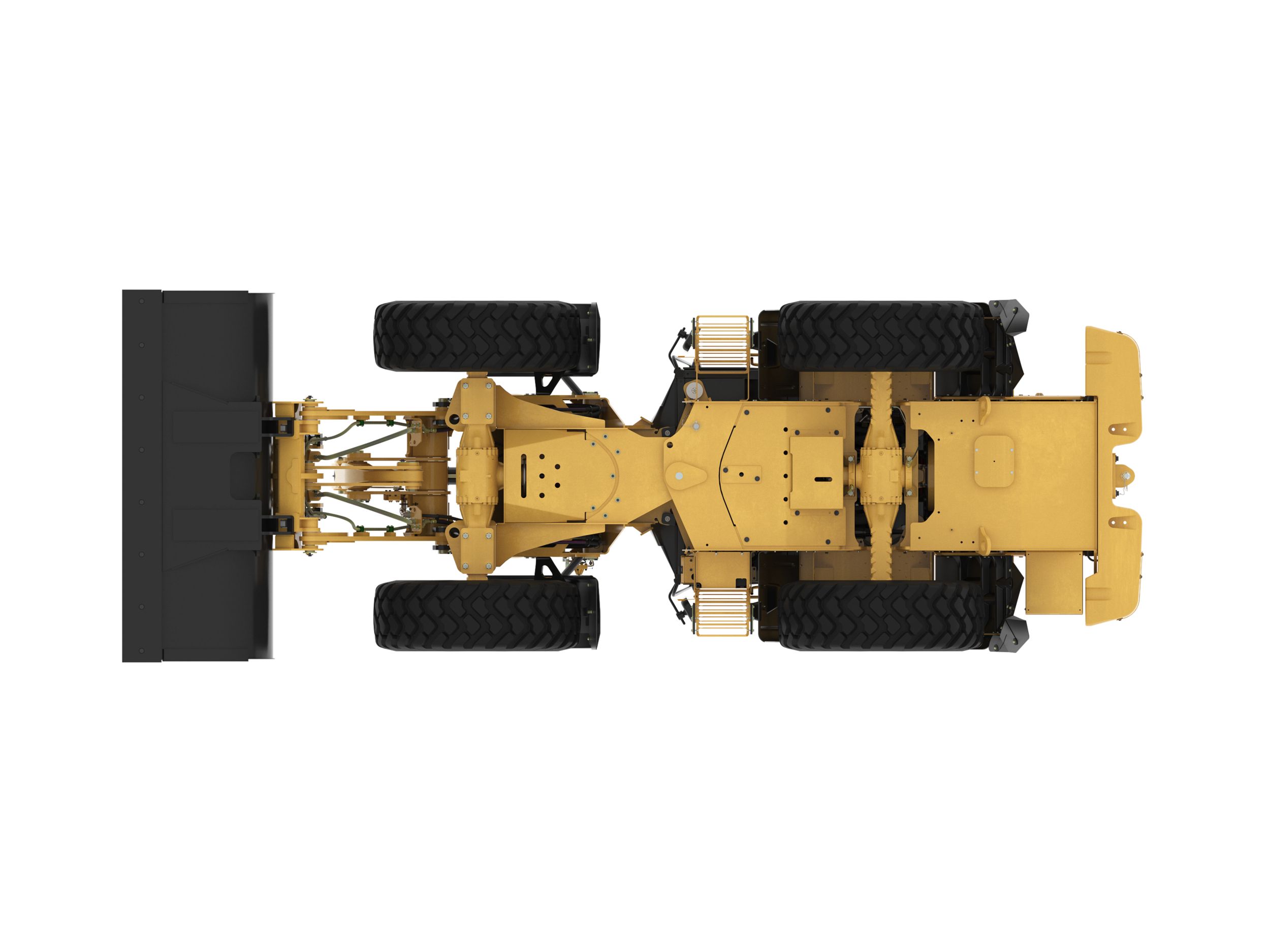

914 Compact Wheel Loader

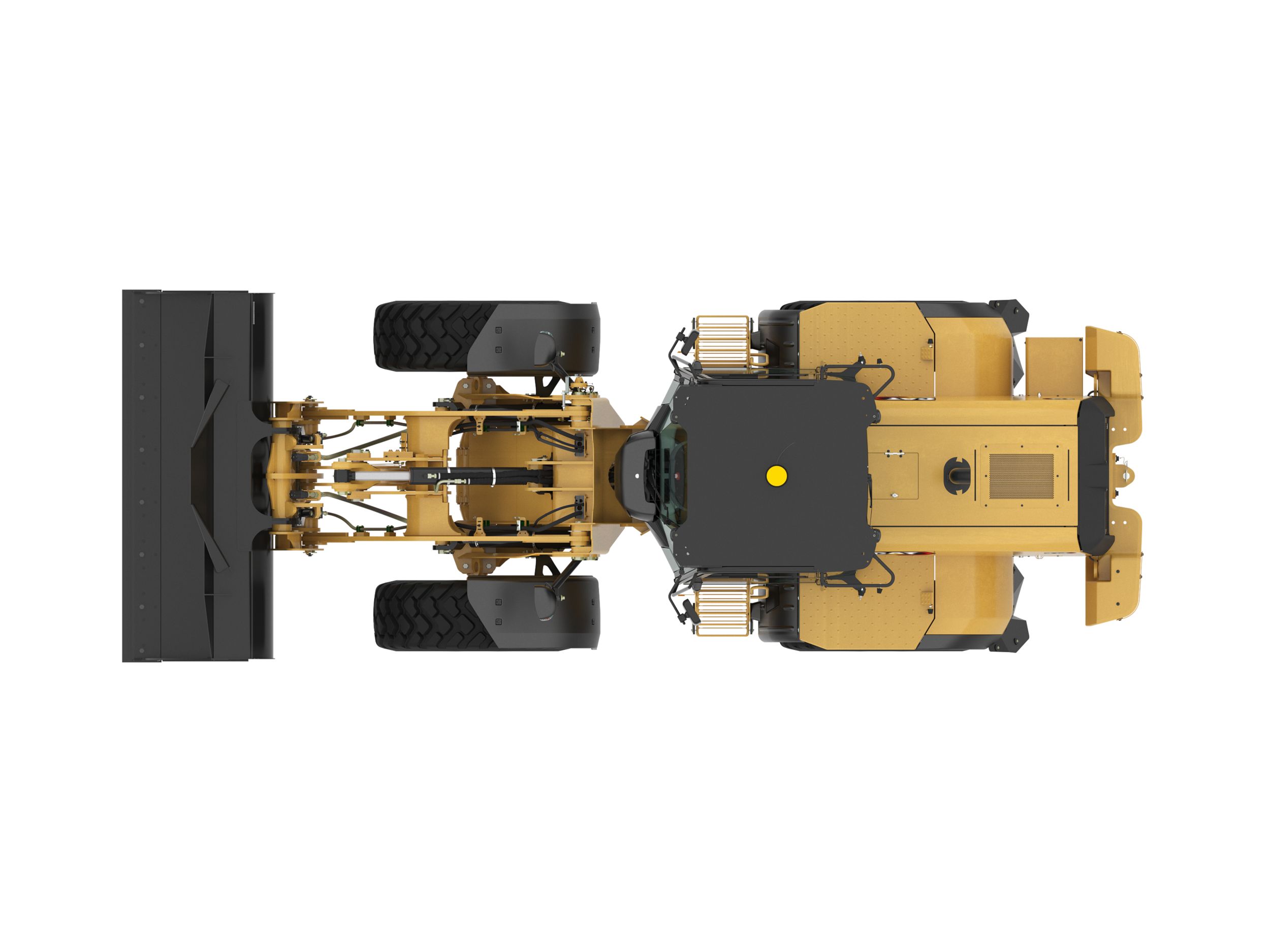

The Cat® 914 Compact Wheel Loader features a C3.6 engine, the Cat Optimized Z-bar Loader linkage, various work tools, a state-of-the-art electro-hydraulic system, a tuned drivetrain, a cab with all-around visibility, extended service intervals and excellent service access, and standard fuel savings features.

Specifications

Product Brochures

Attachments

Units:

Engine

Rated Net Power - Rated Engine Speed

2200 r/min

2200 r/min

Maximum Gross Power - Rated Engine Speed

1800 r/min

1800 r/min

Rated Net Power - SAE J1349

99 hp

74 kW

Maximum Gross Power - ISO 14396 (metric)

112 hp

112 hp

Rated Net Power - ISO 9249

98 hp

73 kW

Maximum Gross Torque - SAE J1995

335 ft·lbf

454 N·m

Maximum Gross Torque - ISO 14396

332 ft·lbf

450 N·m

Maximum Net Torque - SAE J1349

329 ft·lbf

446 N·m

Maximum Net Torque - ISO 9249

327 ft·lbf

443 N·m

Displacement

220 in³

3.6 l

Bore

3.85 in

98 mm

Stroke

4.72 in

120 mm

Engine Model

Cat C3.6

Emissions

Engine meets Tier 4 Final/Stage V emission standards.

Note

Net power advertised is the power available at the flywheel plus front drive implement pump when the engine is equipped with fan, air cleaner, muffler and alternator.

Maximum Gross Power - ISO 14396

110 hp

82 kW

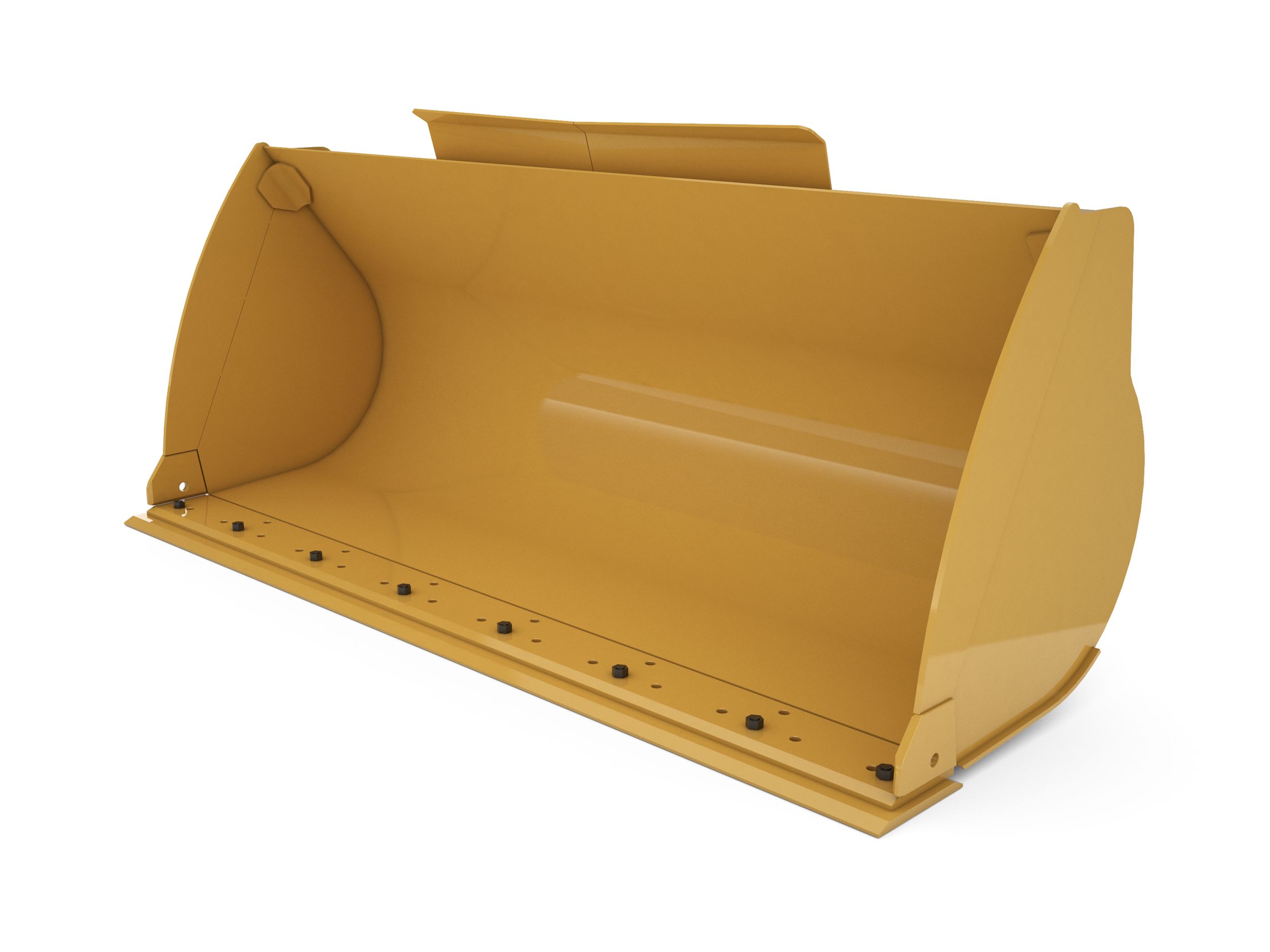

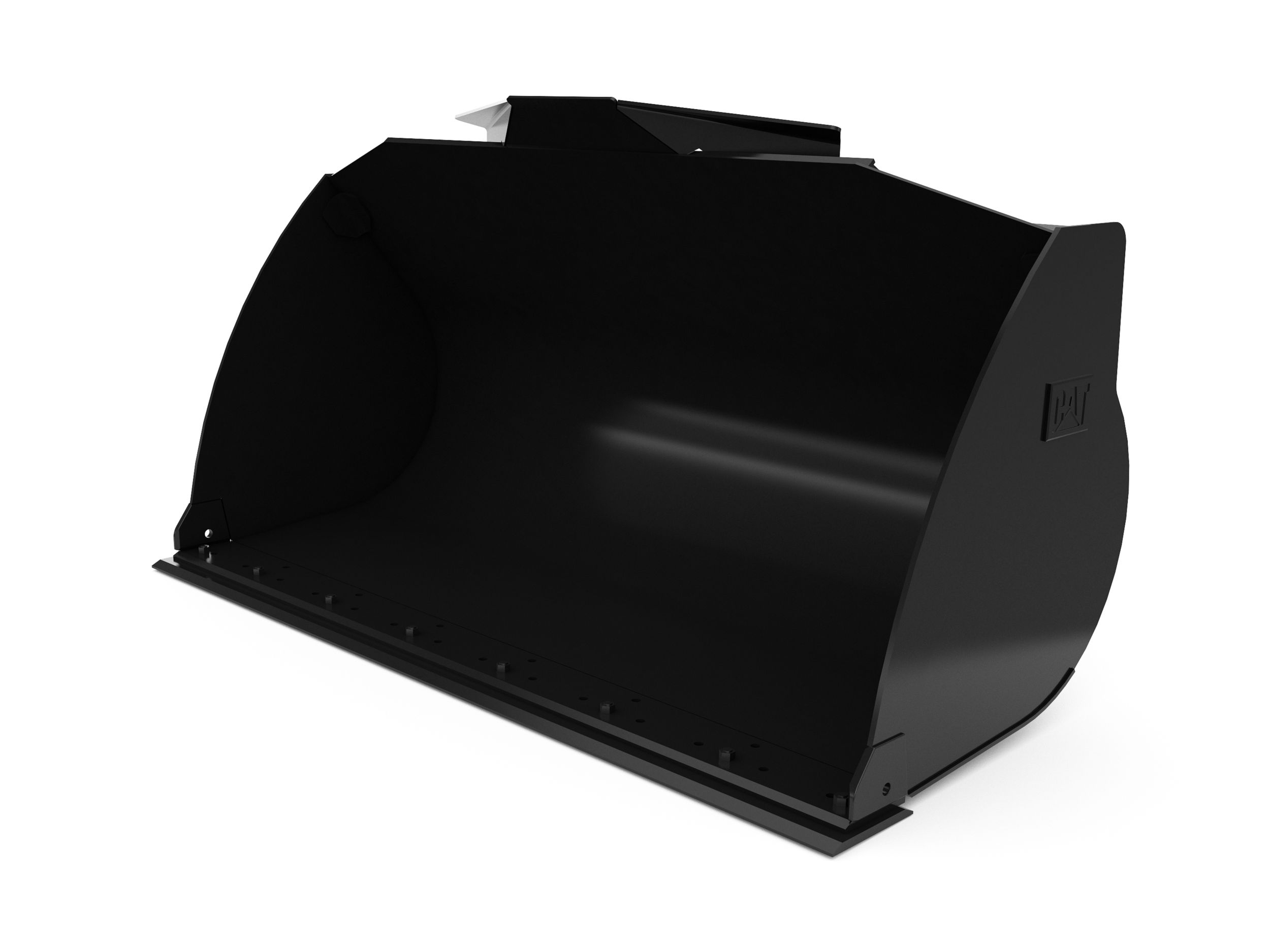

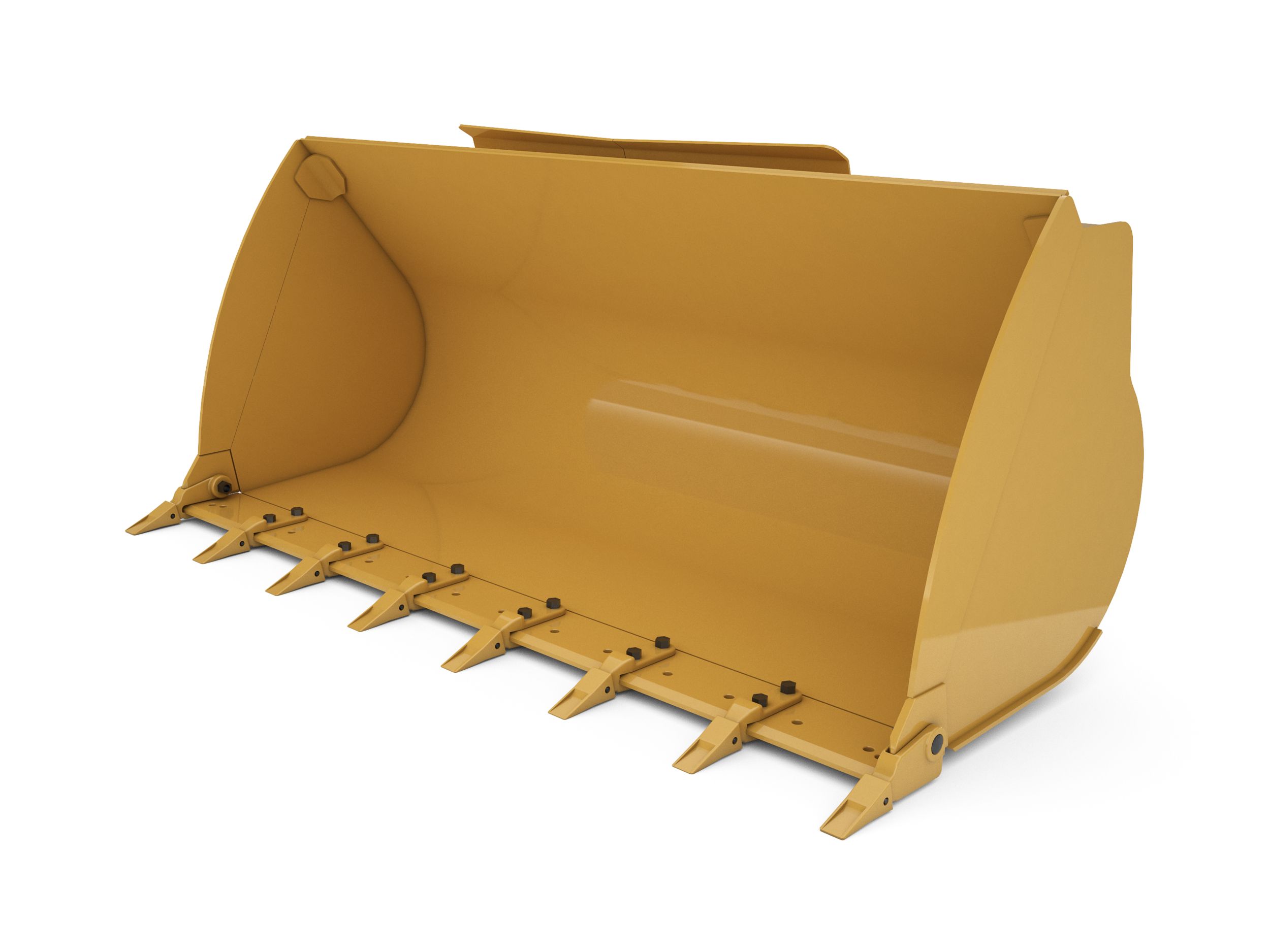

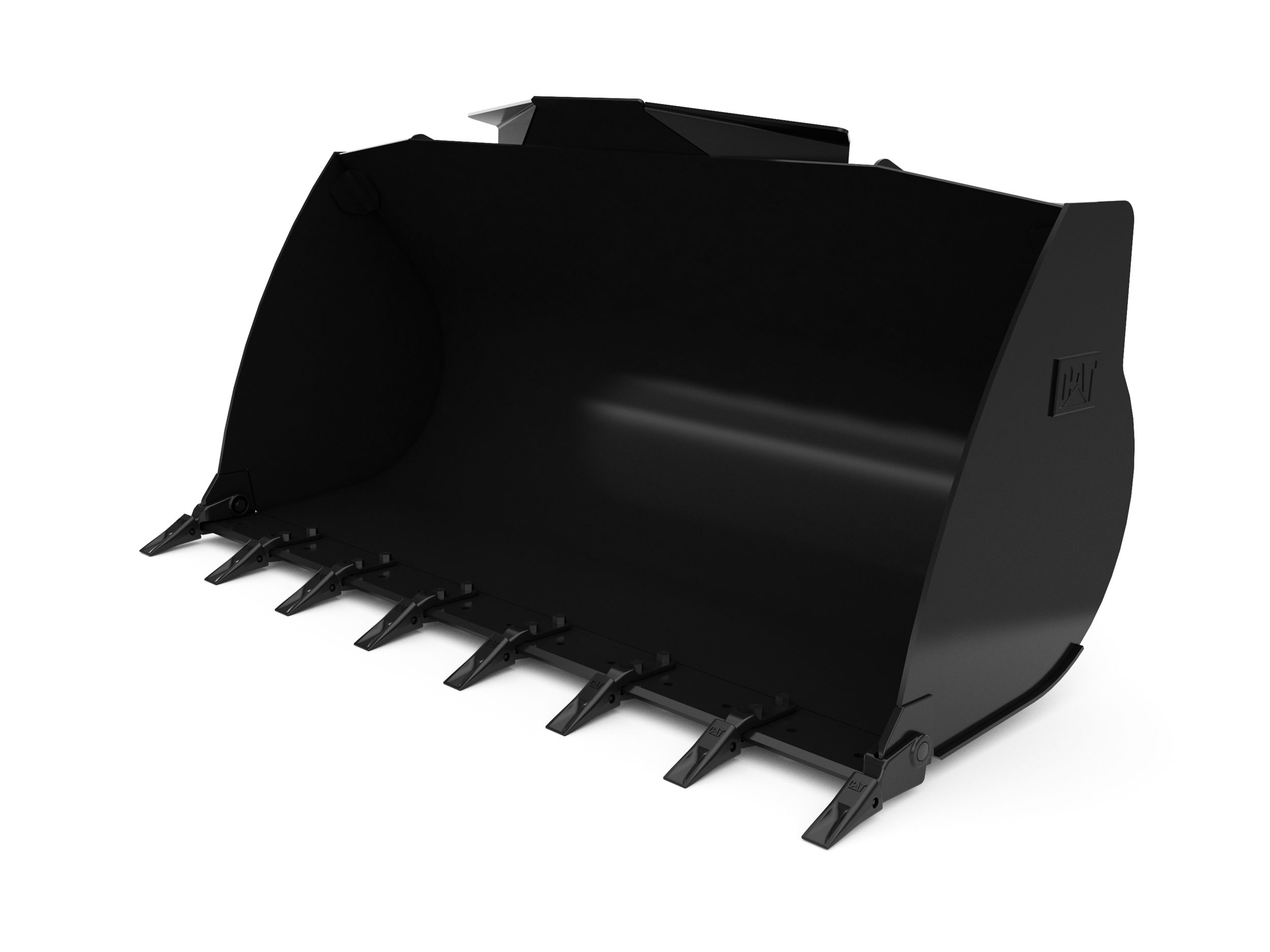

Buckets

Bucket Capacities

1.3-3.5 m3 (1.7-4.6 yd3)

Bucket Capacities - General Purpose

1.3-1.9 m³ (1.7-2.5 yd³)

Bucket Capacities - Light Material

2.5-3.5 m³ (3.3-4.6 yd³)

Weights

Operating Weight

19103 lb

8668 kg

Steering

Maximum Flow - Steering Pump

22 gpm

82 L/min

Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left

3.75 turns

3.75 turns

Steering Cycle Times - Full Left to Full Right - At 2,350 rpm: 90 rpm Steering Wheel Speed

2.8 s

2.8 s

Maximum Working Pressure - Steering Pump

3263 psi

22500 kPa

Steering Articulation Angle - Each Direction

40 °

40 °

Loader Hydraulic System

Relief Pressure - Tilt Cylinder - 3rd Function Maximum Working Pressure

3046 psi

21000 kPa

Maximum Flow - Implement Pump

39 gpm

148 L/min

Maximum Flow - Implement Pump - 3rd Function, Maximum Flow, Standard

24 gpm

90 L/min

Relief Pressure - Tilt Cylinder - 4th Function Maximum Working Pressure

3046 psi

21000 kPa

Hydraulic Cycle Time - Total Cycle Time

12.5 s

12.5 s

Hydraulic Cycle Time - Raise, Ground Level to Maximum Lift

5.2 s

5.2 s

Maximum Flow - Implement Pump - 4th Function, Maximum Flow

24 gpm

90 L/min

Hydraulic Cycle Time - Dump, at Maximum Reach

1.4 s

1.4 s

Relief Pressure - Tilt Cylinder

4931 psi

34000 kPa

Maximum Flow - Implement Pump - 3rd Function, Maximum Flow, High

32 gpm

120 L/min

Maximum Working Pressure - Implement Pump

4061 psi

28000 kPa

Hydraulic Cycle Time - Rackback

2.2 s

2.2 s

Hydraulic Cycle Time - Float Down, Maximum Lift to Ground Level

3.7 s

3.7 s

Service Refill Capacities

Cooling System

5.7 gal (US)

21.5 l

Fuel Tank

43.6 gal (US)

165 l

Note

DEF used in Cat SCR systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241-1.

Axles - Rear Center Differential

2 gal (US)

7.5 l

Hydraulic System - Including Tank

25.9 gal (US)

98 l

Diesel Exhaust Fluid (DEF) Tank

4.8 gal (US)

18 l

Engine Crankcase

2.6 gal (US)

10 l

Hydraulic Tank

14.5 gal (US)

55 l

Transmission

0.8 gal (US)

3.2 l

Axles - Front Center Differential

2 gal (US)

7.5 l

Transmission

Note

*Creeper Control allows speed control from a stand still up to 10 km/h (6.3 mph). The Creeper Control will only work in Range 1.

Forward and Reverse - Speed Range 3

25 mile/h

40 km/h

Forward and Reverse - Speed Range 1*

6.3 mile/h

10 km/h

Forward and Reverse - Speed Range 2*

12.5 mile/h

20 km/h

Tires

Other Choices Include

17.5 R25 L3 XHA2; 17.5-25 L2/L3 SGL; 17.5-25 L3 HRL D/L-3A; 17.5 R25 L2 Snow; 17.5 R25 Solid

Note (1)

Other tire choices are available. Contact your Cat dealer for details.

Standard Size

17.5 R25 L2 XTLA

Note (3)

Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model.

Note (2)

In certain applications, the loader’s productive capabilities may exceed the tire’s tonnes-km/h (ton-mph) capabilities.

Cab

ROPS

ISO 3471:2008

FOPS

ISO 3449:2005

Note (4)

*The measurements were conducted with the cab doors and windows closed.

Note (2)

The declared dynamic operator sound pressure levels per ISO 6396:2008*, when the cab is properly installed and maintained, is 77 dB(A).

Note (3)

The labelled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC (as amended by 2005/88/EC) is 103 dB(A).

Note (1)

Cab and Rollover Protective Structures (ROPS) are standard in North America and Europe.

Axles

Rear

Oscillating ±11 degrees; Locking differential (Standard)

Front

Fixed; Locking differential (standard)

Sustainability

Recyclability

95%

Engine

Maximum Gross Power

110 hp

82 kW