MH3024 Wheel Material Handler

The Cat® MH3024 is a purpose-built material handler designed to deliver strong performance for your toughest waste and scrapyard applications. The MH3024 features simple-to-use technologies, a comfortable cab, and multiple boom and stick options to match your work. These features help create a safe, reliable product to take on the wide variety of challenges you face each day.

Specifications

Equipment

Product Brochures

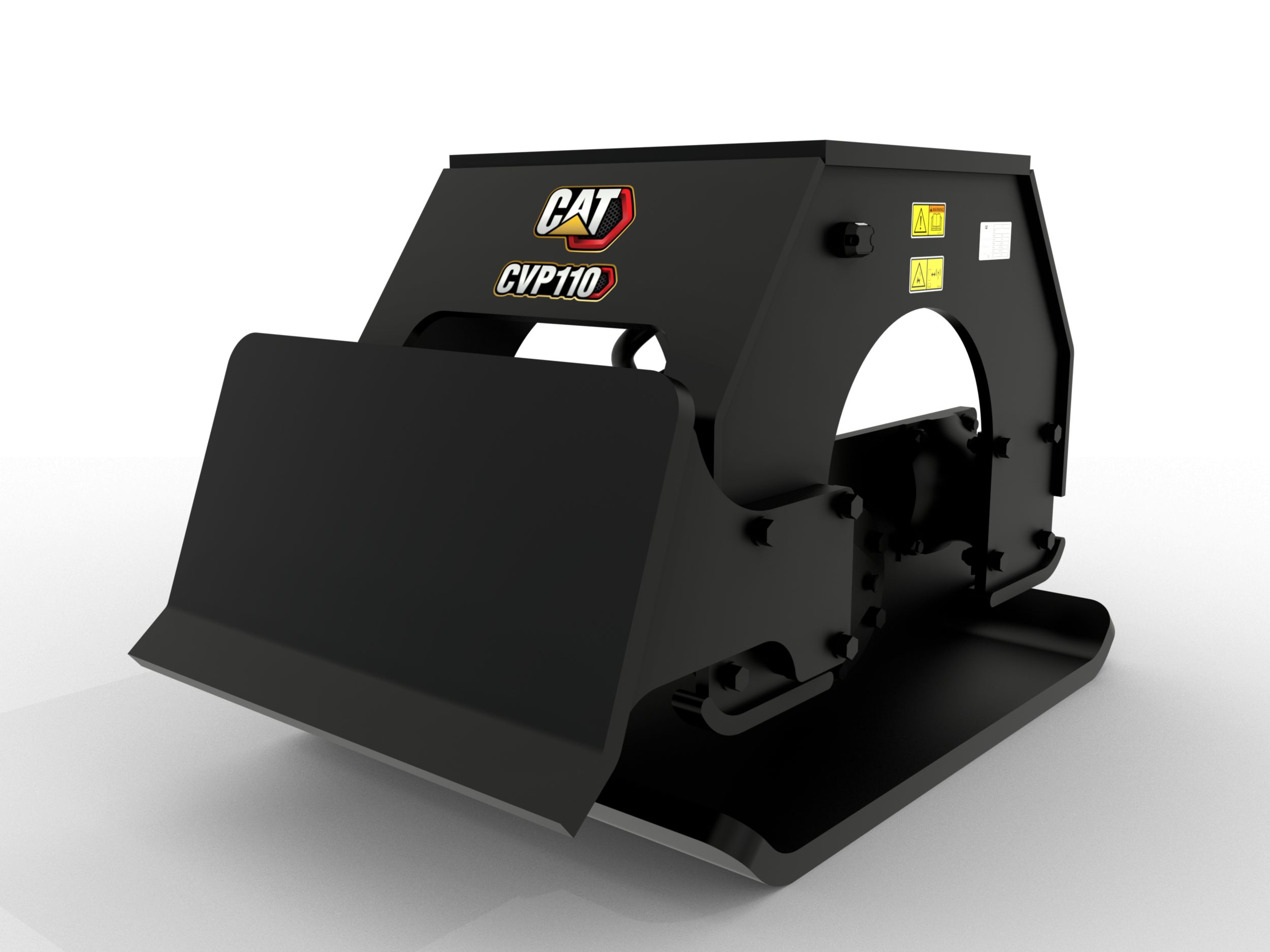

Attachments

Units:

Engine

Engine Model

Cat C4.4

Net Power - ISO 9249

171 hp

128 kW

Net Power - ISO 9249 (DIN)

174 hp (metric)

174 hp (metric)

Engine Power - Maximum - ISO 14396

174 hp

129 kW

Engine Power - ISO 14396 (DIN)

176 hp (metric)

176 hp (metric)

Bore

4.1 in

105 mm

Stroke

5.3 in

135 mm

Displacement

268.5 in³

4.4 l

Biodiesel Capability

Up to B20¹

Emissions

Meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

Note (1)

Net power advertised is the power available at the flywheel when the engine is equipped with fan, air cleaner, Clean Emission Module (CEM) exhaust gas aftertreatment, alternator, and cooling fan running at intermediate speed. Rated speed 2,200 rpm. Advertised power is tested per the specified standard in effect at the time of manufacture.

Note (2)

¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). **Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

Transmission

Maximum Travel Speed

12.4 mile/h

20 km/h

Drawbar Pull

28551 lb/ft

127 kN

Maximum Gradeability

65%

Hydraulic System

Maximum Pressure - Implements

5075 psi

35000 kPa

Maximum Pressure - Swing

5656 psi

39000 kPa

Maximum Pressure - Travel

5075 psi

35000 kPa

Swing Mechanism

Swing Speed

8 r/min

8 r/min

Maximum Swing Torque

42631 lbf·ft

58 kN·m

Weights

Operating Weight

59100 lb

26800 kg

Note

Operating weight includes full fuel tank, operator, 1400 kg (3,086 lb) work tool. Weight varies depending on configuration.

Service Refill Capacities

Fuel Tank Capacity

92.5 gal (US)

350 l

Cooling System

9.5 gal (US)

36 l

Engine Oil

3.4 gal (US)

13 l

Rear Axle - Housing (Differential)

3.7 gal (US)

14 l

Final Drive - Each

0.7 gal (US)

2.5 l

Powershift Transmission

0.7 gal (US)

2.5 l

Hydraulic System - Including Tank

91.1 gal (US)

345 l

Hydraulic Tank

40.9 gal (US)

155 l

Diesel Exhaust Fluid (DEF) Tank

7.9 gal (US)

30 l

Dimensions

Boom

MH 7.45 m (24'5")

Stick

5.0 m (16'5") Drop Nose

Shipping Length

35 ft

10670 mm

Machine Length

17.4 ft

5290 mm

Tail Swing Radius

8.5 ft

2600 mm

Counterweight Clearance

4.3 ft

1300 mm

Cab Height- Lowered

11 ft

3350 mm

Cab Height-Lowered with OPG

11 ft

3350 mm

Cab Height-Raised

18.9 ft

5750 mm

Cab Height-Raised with OPG

18.9 ft

5750 mm

Wheel Base

9 ft

2750 mm

Shipping Width

9.8 ft

2990 mm

Ground Clearance

0.8 ft

240 mm

Undercarriage Length

17.4 ft

5300 mm

Working Ranges

Maximum Reach

39.4 ft

12010 mm

Boom

MH 7.45 m (24'5")

Stick

5.0 m (16'5") Drop Nose

Maximum Height

42.7 ft

13030 mm

Minimum Dump Height

14.8 ft

4520 mm

Maximum Depth

9.9 ft

3010 mm

Boom Pin Height

30.4 ft

9260 mm

Air Conditioning System

Note (1)

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.05 kg (2.31 lb) of refrigerant which has a CO2 equivalent of 1.502 metric tonnes (1.655 tons).

Standard Equipment

NOTE

Cab

Cat Technology

Electrical System

Service and Maintenance

Engine

Hydraulic System

Safety and Security

Undercarriage and Structures