Cat® 336 Hydraulic Excavator

The Cat® 336 is a product of Caterpillar's time-proven engineering and manufacturing know-how for top-notch quality, reliability, and durability. The Cat® C7.1 engine and cutting-edge electrohydraulic system work together to help you power through all types of work quickly and efficiently. This multi-purpose machine is available in multiple configurations and is compatible with many attachments. Engineered for durability, the reinforced booms, sticks, and frames are built to last. Our Cat® Next Generation Excavators share common parts, exceptional customer service, and superior product support, giving you more uptime. Using Cat® long-life fuel and hydraulic oil filters with extended and synchronized service intervals in your 336 will help reduce maintenance costs and downtime.

Specifications

Equipment

Product Brochures

Attachments

Engine

Net Power - ISO 9249

300 hp

223.5 kW

Net Power - ISO 9249 (DIN)

304 hp (metric)

304 hp (metric)

Engine Model

Cat C7.1 TTA

Engine Power - ISO 14396

302 hp

225 kW

Engine Power - ISO 14396 (DIN)

306 hp (metric)

306 hp (metric)

Displacement

428 in³

7.01 l

Biodiesel Capability

Up to B20¹

Emissions

Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014

emission standards.

Note (1)

Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system, and alternator with engine speed at 2,000 rpm. Advertised power is tested per the specified standard in effect at the time of manufacture.

Note (2)

¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or "Caterpillar Machine Fluids Recommendations" (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). **Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

Hydraulic System

Main System - Maximum Flow

148 gpm

560 L/min

Maximum Pressure - Equipment

5076 psi

35000 kPa

Maximum Pressure - Equipment - Lift Mode

5511 psi

38000 kPa

Maximum Pressure - Travel

5076 psi

35000 kPa

Maximum Pressure - Swing

4264 psi

29400 kPa

Swing Mechanism

Maximum Swing Torque

105250 lbf·ft

143 kN·m

Note (1)

*For CE-marked machine default value may be set lower

Weights

Operating Weight

81100 lb

36800 kg

Service Refill Capacities

Fuel Tank Capacity

158.5 gal (US)

600 l

Cooling System

10.2 gal (US)

39 l

Engine Oil

6.6 gal (US)

25 l

Swing Drive - Each

4.8 gal (US)

18 l

Final Drive - Each

2.1 gal (US)

8 l

Hydraulic System - Including Tank

98.5 gal (US)

373 l

Hydraulic Tank

42.5 gal (US)

161 l

DEF Tank

13.2 gal (US)

50 l

Dimensions

Transport Width

10.5 ft

3190 mm

Stick

Reach 3.9 m (12'10")

Bucket

HD 2.00 m³ (2.61 yd³)

Shipping Height - Top of Cab

10.5 ft

3180 mm

Handrail Height

10.5 ft

3180 mm

Shipping Length

36.8 ft

11180 mm

Tail Swing Radius

11.7 ft

3530 mm

Counterweight Clearance

4.2 ft

1260 mm

Ground Clearance

1.8 ft

510 mm

Track Length

16.6 ft

5030 mm

Track Length to Center of Rollers

13.3 ft

4040 mm

Transport Width - 850 mm (33”) Shoes

11.9 ft

3590 mm

Working Ranges and Forces

Maximum Digging Depth

26.11 ft

8210 mm

Stick

Reach 3.9 m (12'10")

Bucket

HD 2.00 m³ (2.61 yd³)

Maximum Reach at Ground Level

38.7 ft

11760 mm

Maximum Cutting Height

35.3 ft

10740 mm

Maximum Loading Height

24.6 ft

7470 mm

Minimum Loading Height

6.2 ft

1890 mm

Maximum Depth Cut for 2440 mm (8 ft) Level Bottom

26.6 ft

8080 mm

Maximum Vertical Wall Digging Depth

21.4 ft

6490 mm

Bucket Digging Force - ISO

47190 lbf·ft

210 kN

Stick Digging Force - ISO

32480 lbf·ft

144 kN

Air Conditioning System

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.00 kg of refrigerant, which has a CO2 equivalent of 1.430 metric tonnes.

Standard Equipment

UNDERCARRIAGE AND STRUCTURES

Multi-Processor with Concrete Cutter Jaws

Multi-Processor with Demolition Jaws

Multi-Processor with Pulverizer Jaws

Multi-Processor with Shear Jaws

Multi-Processor with Tank Shear Jaws

Multi-Processor with Universal Jaws

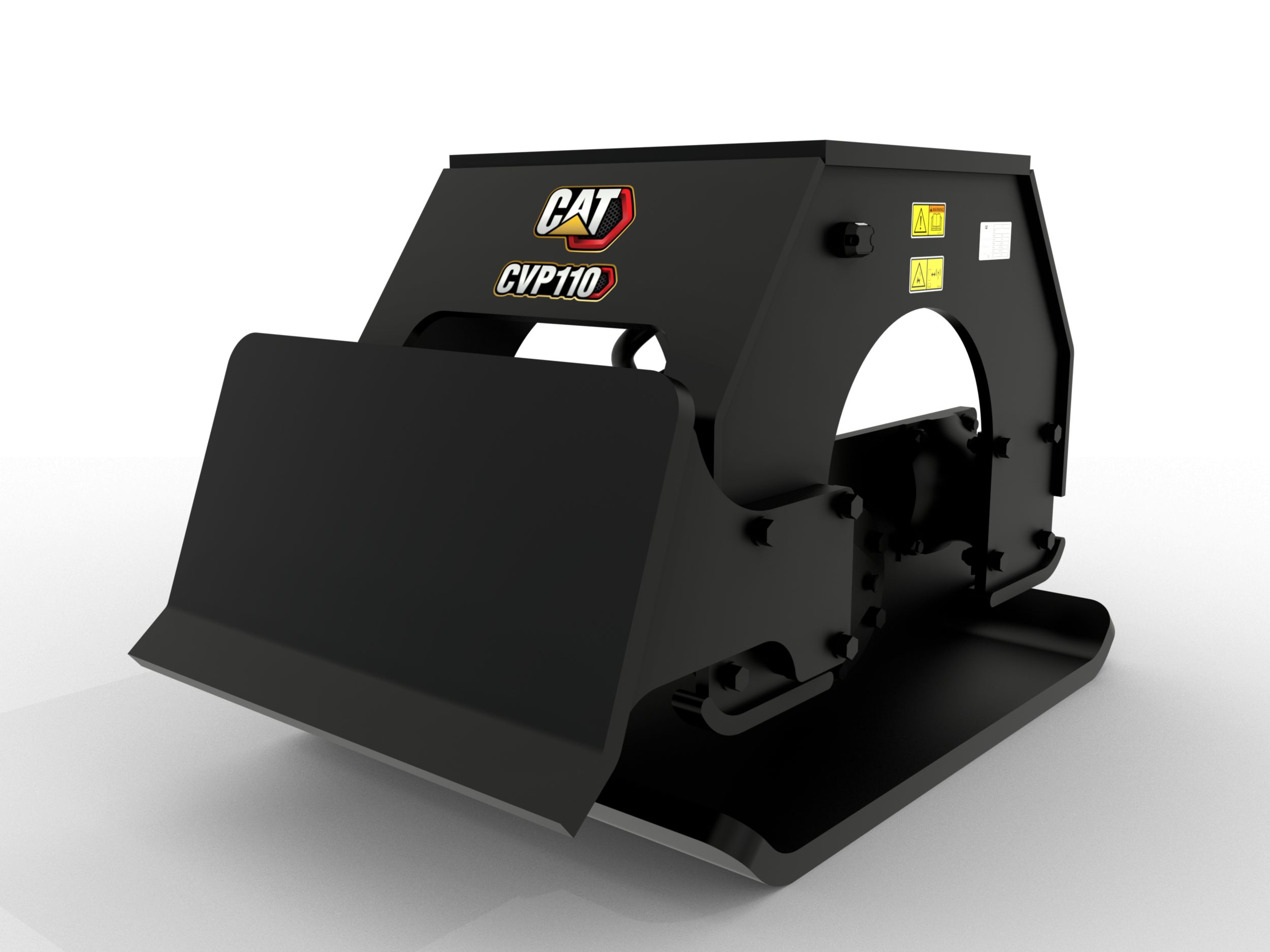

Vibratory Plate Compactors